PASCAM Part description

|

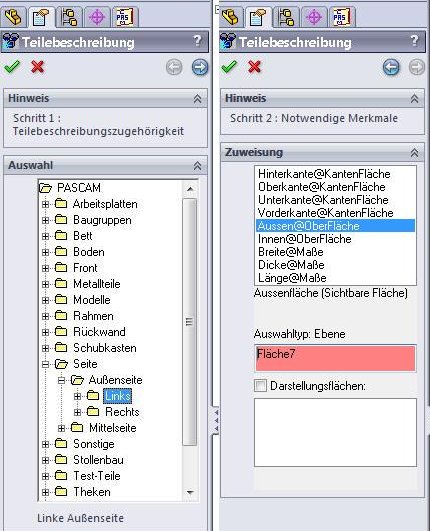

A central component of

PASCAM WoodWorks is the part description. You can assign specific dimensions and faces to a part by using properties. Based on this data, parts list information can be derived in the background. Subsequently automatic mating is also available with the PASCAM mate manager, based on the part description. The PASCAM Part description can be applied to any SOLIDWORKS®

part or assembly. It is specifically defined by the

individual user. |

For a rapid build up of new assemblies from scratch the intelligent PASCAM database parts can be retrieved from the PASCAM database and directly applied at the new assembly. As the intelligent database part has got the information for its correct position in the assembly by the user via the PASCAM Part description and is thus equipped with semantic parametrics, the inserting and assembling of the individual components is carried out more or less automatically. The applied intelligent database part "knows" so to say "what it is", e.g. the left side part of a cabinet case furniture.

The effort to achieve a comprehensive description of this semantic parts is minimal and is provided by a user-friendly interface, which also allows you to save the defined parts in distinguished PASCAM part databases and libraries for easy re-use. The additional time needed in the primary design process pays off immediately, when those intelligent database parts are applied safe and quickly at a basically new design process, at a variant design process of an existing product model or when the intelligent parts are exchanged quickly and associatively in conjunction with other installed components in the assembly. The parametric information of the applied database components is always available and can be modified and controlled as needed directly in the assembly (e.g., the individual component size is controlled by changing the outside dimension of the assembly). Modified components can then be stored as new PASCAM database parts.

All of the database parts and materials are generally open for modifications and can be edited by any authorised user; this applies also to adding newly created elements for the PASCAM databases and libraries. The "intelligent" database parts serve for a higher degree of efficiency and increased design safety when applied in other assemblies, whether those are newly created and assembled from scratch or a variant is designed of an existing product model. Access to the company-wide PASCAM databases can be provided to all members of the design team. At this knowledge-based design process all the practical experiences and best design ideas of the individual team members can be stored in the PASCAM databases and libraries, gradually forming an effective collection of standardized design know-how of the user company, which is available to all designers and supports the overall productivity of the whole design department.