Material management

You will notice that PASCAM WoodWorks doesn't stop at the quick modification of model geometry but is also very powerful at the material management of your model assembly. PASCAM WoodWorks enables with its enhanced material management full associativity and continuous, unbroken data flow between the model geometry and the applied materials as well as enhanced efficiency by controlling the applied materials by means of material equations.

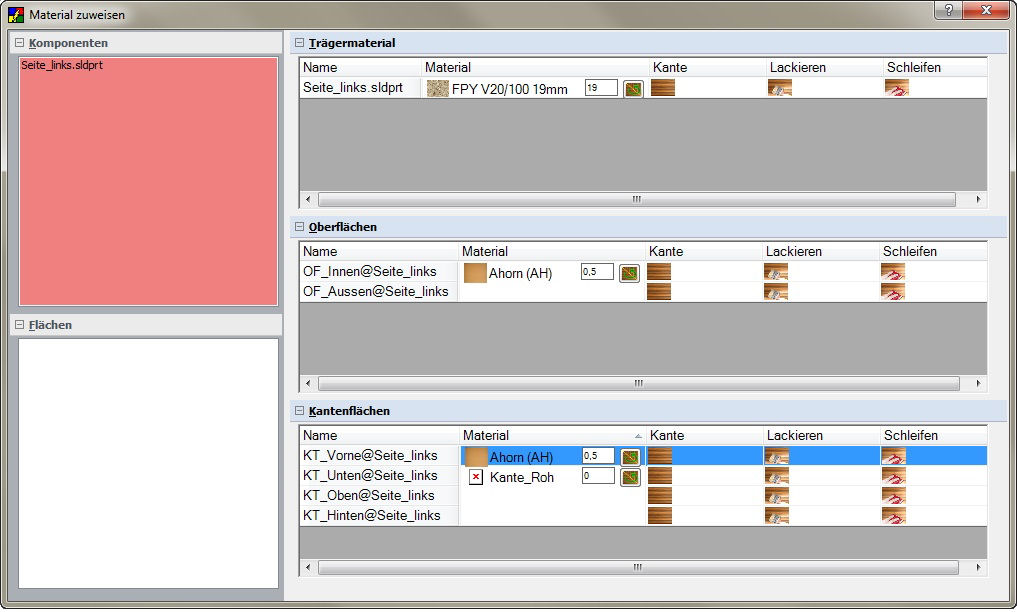

In a first step in the design process you are able to define at the PASCAM Part description, which materials shall be assigned to which faces of the model assembly (see i.e. the user dialog box for "Material application"). In a subsequent design process step the applied materials can be modified comprehensively, just by exchanging the existing material definition in the PASCAM Material manager.

Apart from the actual material of the assembly parts, consisting e.g. of FPY particle board as the carrier component and the veneer or decal materials for the separate surfaces and edges of the parts, you are also able to apply specific information for surface finishes and machining as well as as for varnish and sanding. This comprehensive material information is also available to export at the PASCAM wood list or any other exported list files, if needed.

Woodworkers with very high requirements on surface material (photorealism, etc.) are able to create an individual user material data base with individual decal pictures, user-defined material definitions and specific material properties.

At this short video sequence you can see, how easy it is to assign woodworking carrier material, as well as all necessary surface and the edging materials to your cabinet parts: